With our advanced flow channel analyzing software and more than 10 years' design and production experience,we can supply our customers the most suitable feed block with the strongest practicality. In particular,the inlet and outlet dimension of feed block can be customized to connect directly with extruder and die,without requesting for transition part thus save the cost.

· Accurate flow channel design assures perfect processing precision.

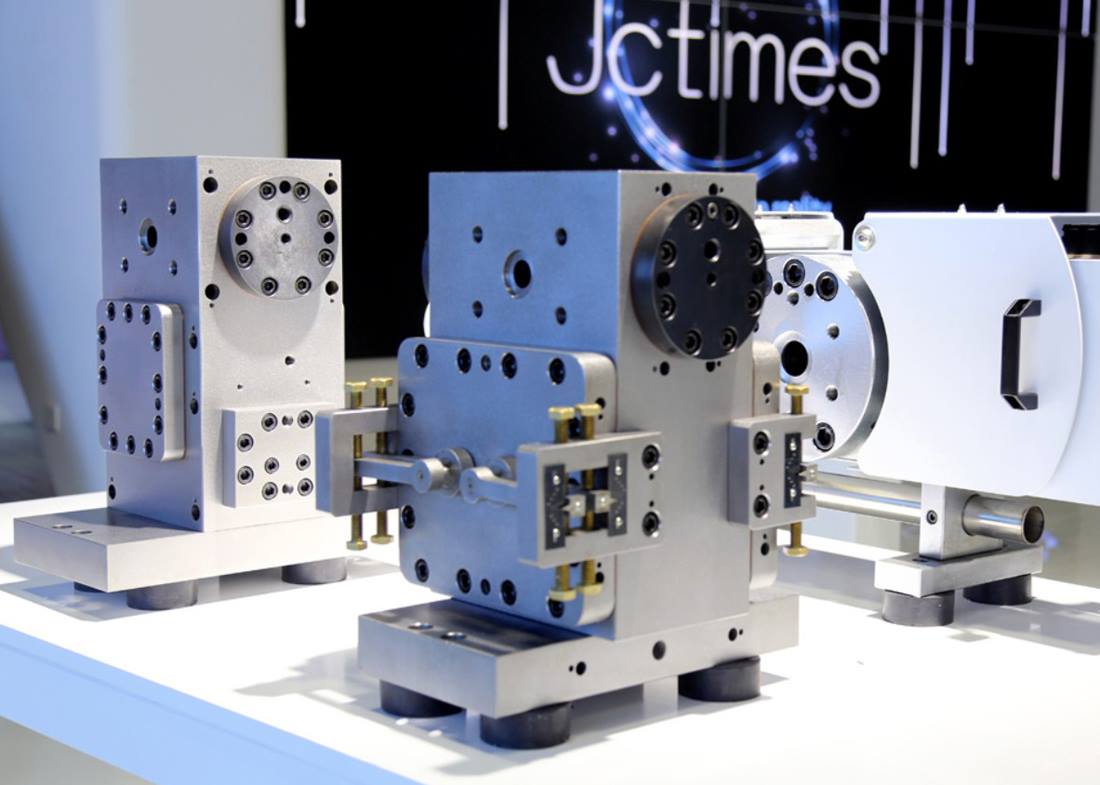

Other Products

Other Products