· The most optimized coat-hanger flow channel will be design,according

to polymers'different characteristics,including viscosity,processing

temperature and flow velocity,thus make melt distribution more uniform.

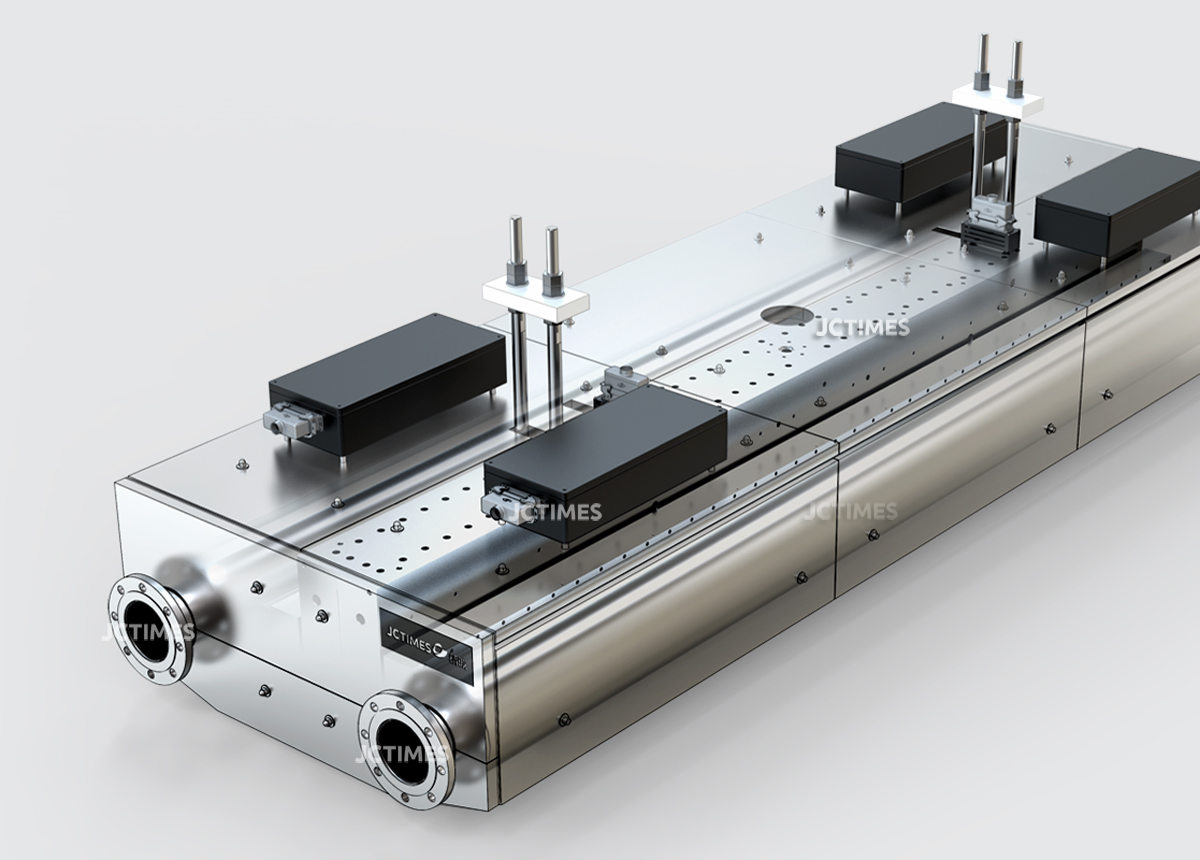

· Roughness of mold cavity is at 0.01um-0.03um

· The special heating device is with high efficiency of heating and heat exchanging, while with low energy consumption.

· Special air chute structure makes air pressure stable and air flow of both sides symmetrical.

· Width of air gap can be adjusted easily and real-timely.

Other Products

Other Products