JCTIMES owns world-advanced R&D technology for extrution die production.We've accumulated production data of more than 35,000 dies,ensuring to supply dies with stable quality and innovation.There are more than 300 sets of 2100mm PC hollow profile dies and 200 sets of PP hollow profile dies with different specifications serving at our global customers' factories.

Extruded hollow board has remarkable characteristics such as anti-fire,heat insulation,UV protection,shock resisting and high transparency.

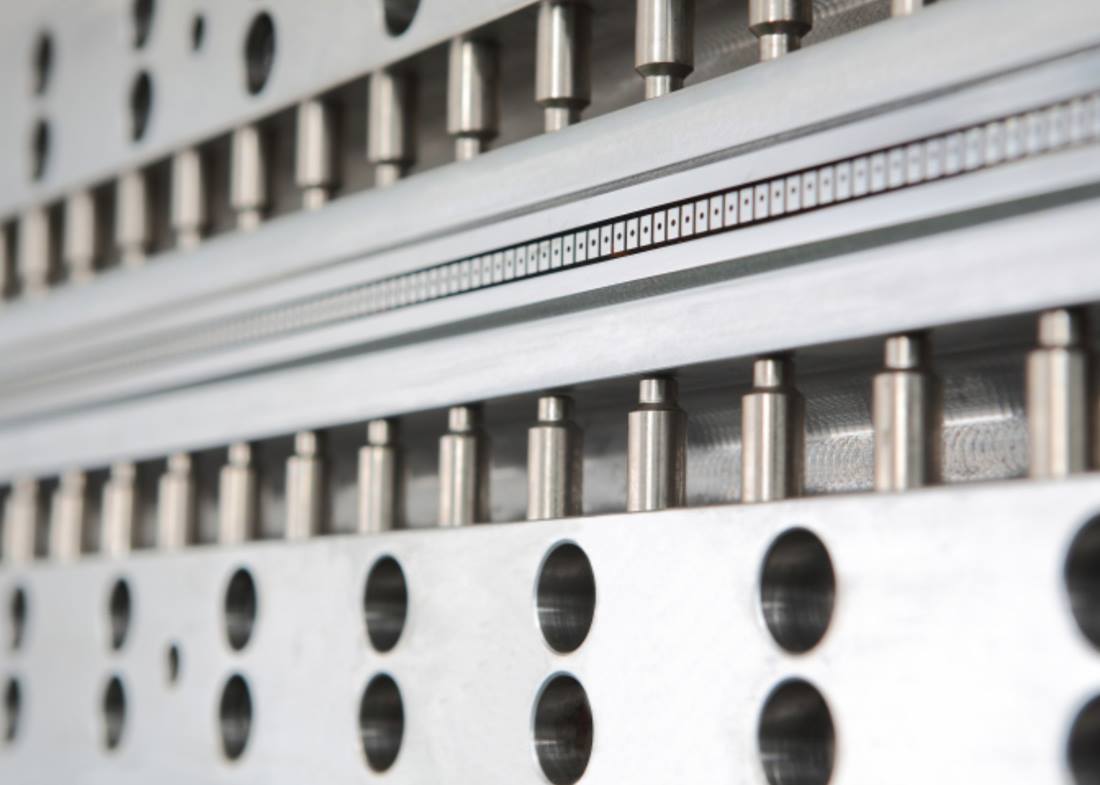

· For the male, the tooth's roughness is finished at 0.04-0.05μm。

· PP hollow sheet die, product thickness ranges from 2-12mm , width 1200-3000mm.

Main type:Twin wall,honey comb,X type.

· Fine adjustment system is easily operated.

· UV+PC+UV,UV+PC co-extruded hollow sheet, made by our hollow sheet die and multi-layer feed block,saving the cost of UV up to 30%.

Flow channel is designed in herring bone structure,making melt flow go more fluently

Other Products

Other Products